Robotic vehicles can have a wide variety of drive mechanisms that range from a simple tricycle setup all the way to crawling legs. Alex Le’s project leverages the reliability of LEGO blocks with the customizability of 3D-printed pieces to create a highly mobile omnidirectional robot called Swervebot, which is controllable over Wi-Fi thanks to an Arduino Nano ESP32.

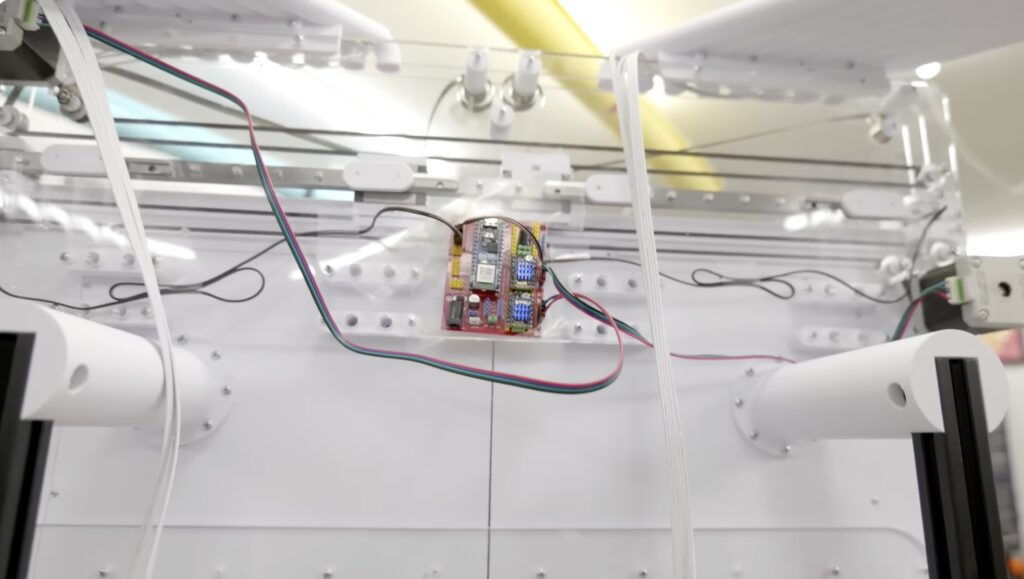

The base mechanism of a co-axial swerve drive robot is a swerve module that uses one axle + motor to spin the wheel and another axle + motor to turn it. When combined with several other swerve modules in a single chassis, the Swervebot is able to perform very complex maneuvers such as spinning while moving in a particular direction. For each of these modules, a pair of DC motors were mounted into custom, LEGO-compatible enclosures and attached to a series of gears for transferring their motion into the wheels. Once assembled into a 2×2 layout, Le moved onto the next steps of wiring and programming the robot.

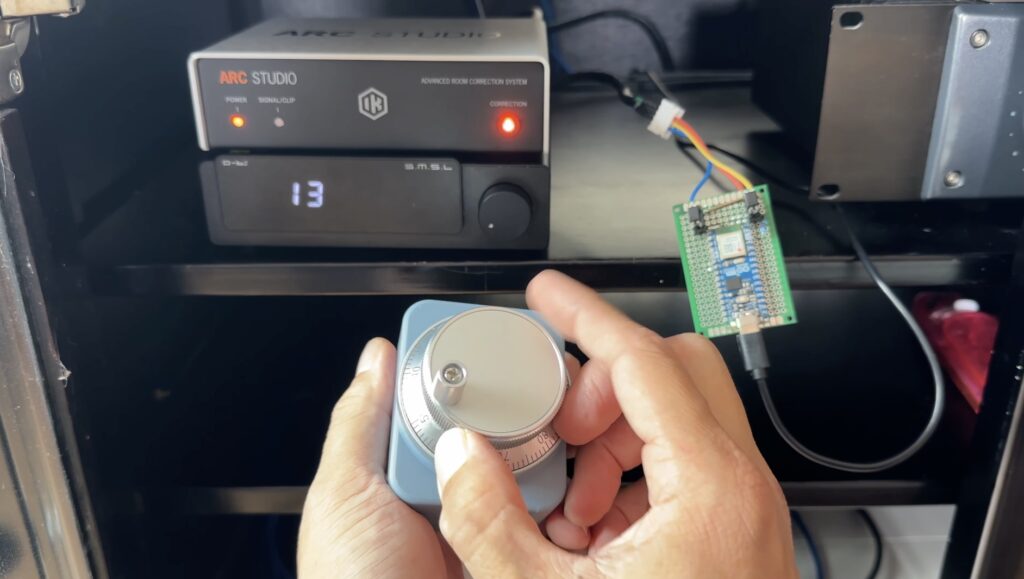

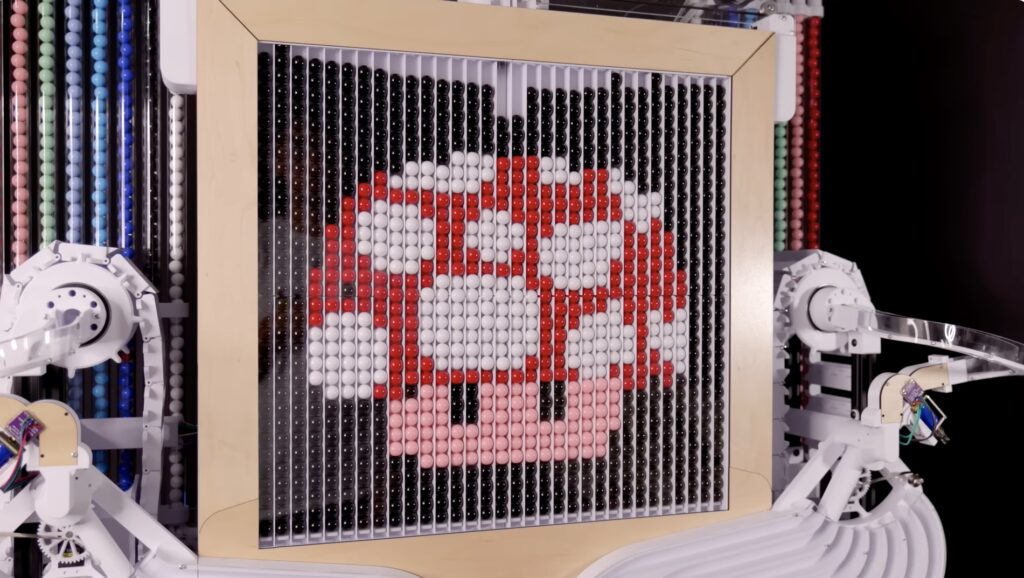

The Nano ESP32 is attached to two TB6612 motor drivers and a screen for displaying fun, animated eyes while the robot is in-motion or idling. Controlling the swerve bot is easy too, as the ESP32 hosts a webpage full of buttons and other inputs for setting speeds and directions.

For more details on the Swervebot, you can read Le’s write-up here on Instructables.

The post The Swervebot is an omnidirectional robot that combines LEGO and 3D-printed parts appeared first on Arduino Blog.